Descripton

The YBM22 series prefabricated substation represents an integrated power distribution solution. It ingeniously combines high - voltage electrical equipment, transformers, and low - voltage electrical equipment into a compact, modular unit. Tailored for diverse application scenarios, it proves ideal for urban high - rise buildings, urban and rural infrastructure projects, residential communities, high - tech development zones, small and medium - sized factories, mining operations, oilfields, as well as temporary construction sites. Serving as a dependable and efficient option, it facilitates the reception and distribution of electrical energy within power distribution systems.

-

Compact & Robust Design:The YBM22 series substation boasts a compact, space - saving structure. With a footprint just 1/10 to 1/5 of traditional substations, it drastically cuts design/construction workloads and overall project costs.

-

High Reliability & Safety:Engineered for stable, secure operation, it minimizes downtime and delivers strong performance even in harsh environments, ensuring power supply continuity.

-

Easy Maintenance & Mobility:Modular architecture simplifies upkeep. It also supports flexible relocation, suiting both permanent deployments (e.g., industrial parks) and temporary sites (e.g., construction projects).

-

Versatile Applications:Compatible with radial/terminal distribution networks, it integrates seamlessly into diverse power systems, adapting to varied operational needs (urban grids, industrial zones, etc.).

-

Standard Compliance:Aligned with GB/T 17467 - 1998 (national standard for HV/LV prefabricated substations), it guarantees top - tier performance and safety, meeting regulatory and reliability demands.

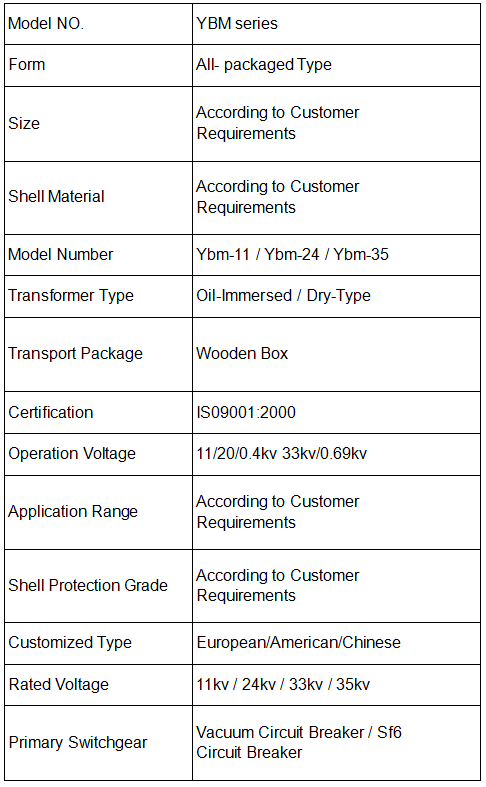

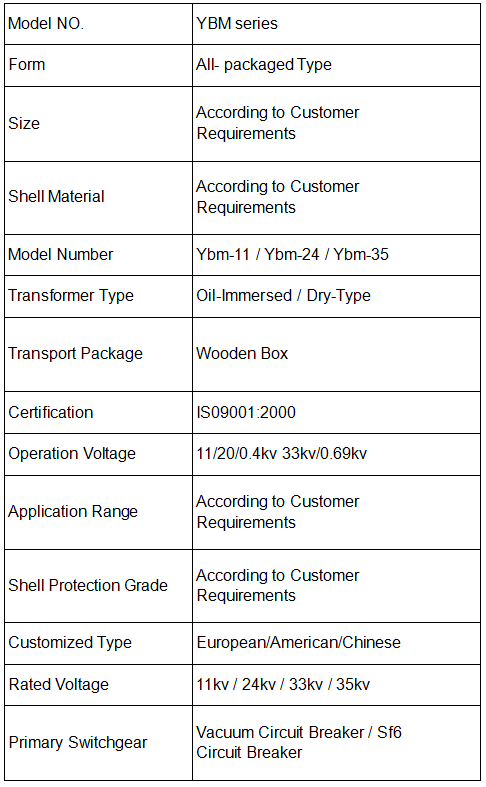

Technical Parameters

-

Space Efficiency:The compact structural design drastically cuts down the required installation area. It becomes the go - to choice for locations where space is at a premium, like crowded urban plots or sites with limited land availability.

-

Cost - Effectiveness:Compared with traditional substations, it slashes construction and installation expenses. From reduced civil engineering work to simplified on - site assembly, it trims costs at every stage of deployment.

-

Rapid Deployment:Thanks to prefabricated, modular components, the installation and commissioning processes are significantly accelerated. It can be quickly put into operation, shortening project timelines for urgent power - supply needs.

-

Scalability:It adapts seamlessly to diverse power distribution requirements, covering both small - scale setups (e.g., a single commercial building) and medium - scale projects (e.g., an industrial park). Modules can be added or adjusted as power demands evolve.

-

Urban & Rural Power Distribution Networks:Serves as a core power distribution node for city grids and rural power systems, optimizing power allocation in both densely - populated urban areas and dispersed rural regions.

-

Residential & Commercial Developments:Ideal for residential communities, shopping malls, office complexes, etc. Ensures stable power supply for daily living and commercial operations, matching the dense load characteristics of such scenarios.

-

Industrial Facilities:Supports power - intensive industrial sites like factories (manufacturing plants), mines (mining operations), and oilfields (petroleum extraction). Delivers reliable power to sustain continuous production processes.

-

Temporary Power Supply for Construction Sites:Meets the transient power needs of infrastructure projects (roads, bridges, buildings). Its easy - relocation design aligns with the dynamic nature of construction phases.

-

High - Tech & Development Zones:Provides stable, high - reliability power for technology parks, R & D centers, and innovation zones. Matches the strict power quality requirements of precision equipment and digital infrastructure.